The ubiquity of the smartphone has also delivered one of the best hardware fixtures that current users cannot do without — the camera, and while brands focus on megapixels, image processing and camera lenses, Apple also has durability in mind when it designs its hardware.

During a recent hosted visit to Apple’s durability lab in Singapore, the global tech giant pulled back the curtains, in one of the few times it has openly provided behind-the-scenes access, to reveal firsthand how it tests the strength of the iPhone camera modules, and the process is much tougher than most people would imagine.

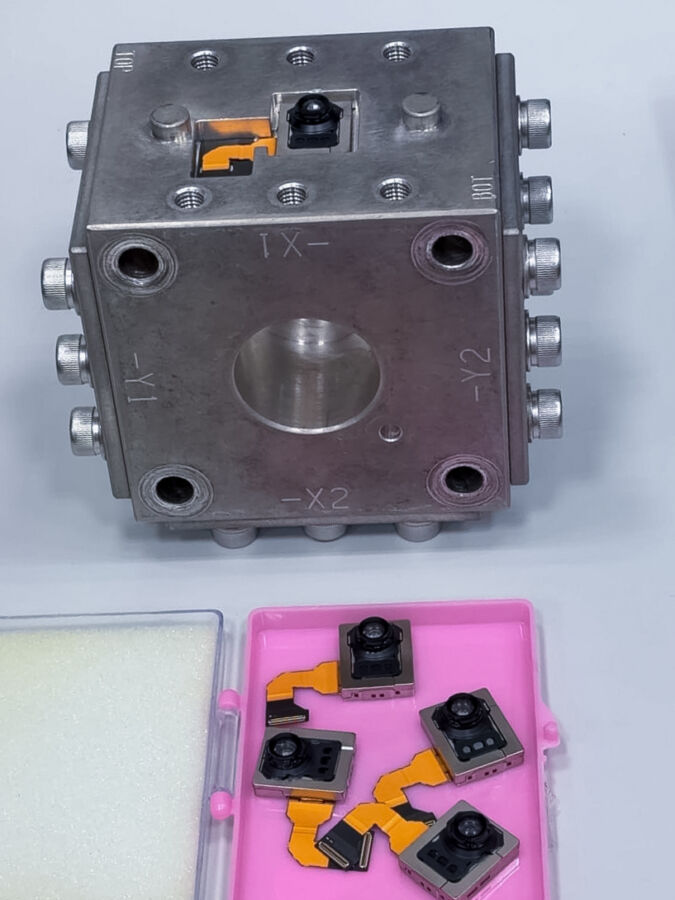

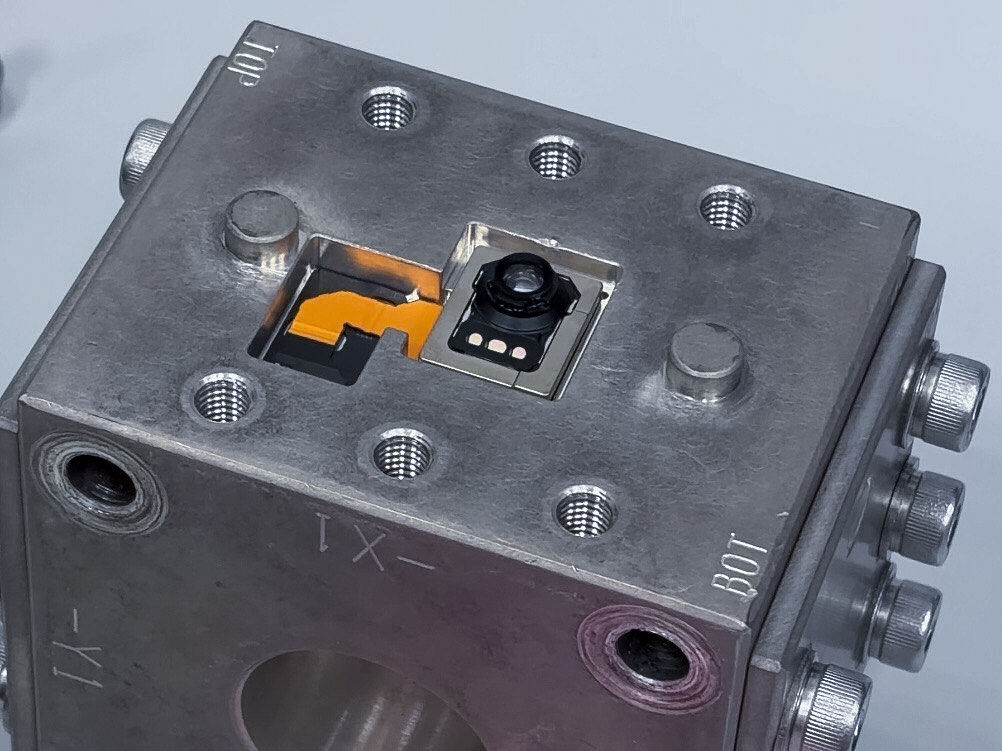

Hardware tests to measure the durability of an electronic product are a given, but a comprehensive suite of environmental, mechanical, and electrical tests designed measure the durability of one camera module, to simulate harsh, real-world conditions and beyond?

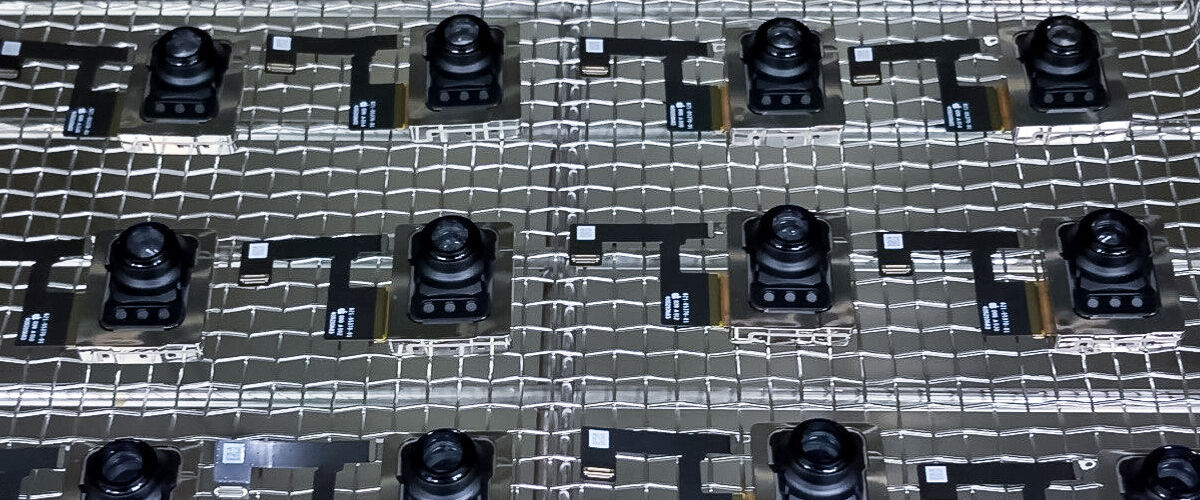

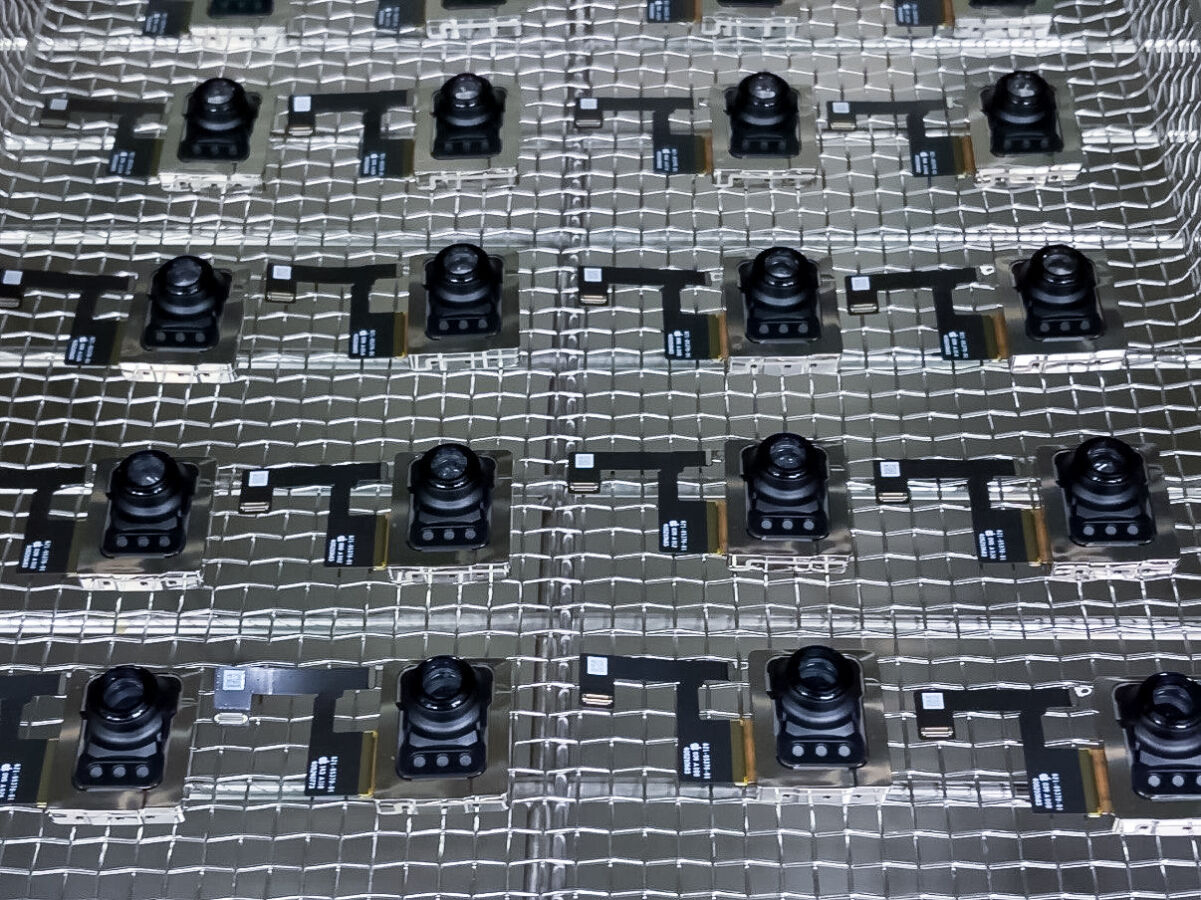

Apple’s presence in Singapore dates back to 1981, with its first campus in Ang Mo Kio, and its presence here — spanning several locations — includes Southeast Asia’s first Apple Developer Centre and now, a major centre for engineering and research. This includes work on the camera module to improve photo-taking and depth-sensing technology, where it supports development and test systems, including Optical Image Stabilisation (OIS), Face ID, LiDAR Scanner, telephoto cameras, and sensor-shift.

And then there’s the durability lab, where one of the key focuses is the camera, which is evaluated under long-term, extreme conditions to ensure it continues to perform well over time. This includes ensuring the module’s structural integrity, which is essential for long-term performance, as well as rigorous testing to identify weaknesses that may not appear until prolonged or even strenuous use.

Before entering the lab, we spoke with Tom Marieb, Vice President of Product Integrity, who explained Apple’s approach to durability and noted that user feedback, especially when it points out issues, is a key driver for improvement.

One main takeaway was on how closely Apple’s testing mirrors real user behaviour, as the four tests they presented covered multiple simulated scenarios which smartphone users might find familiar.

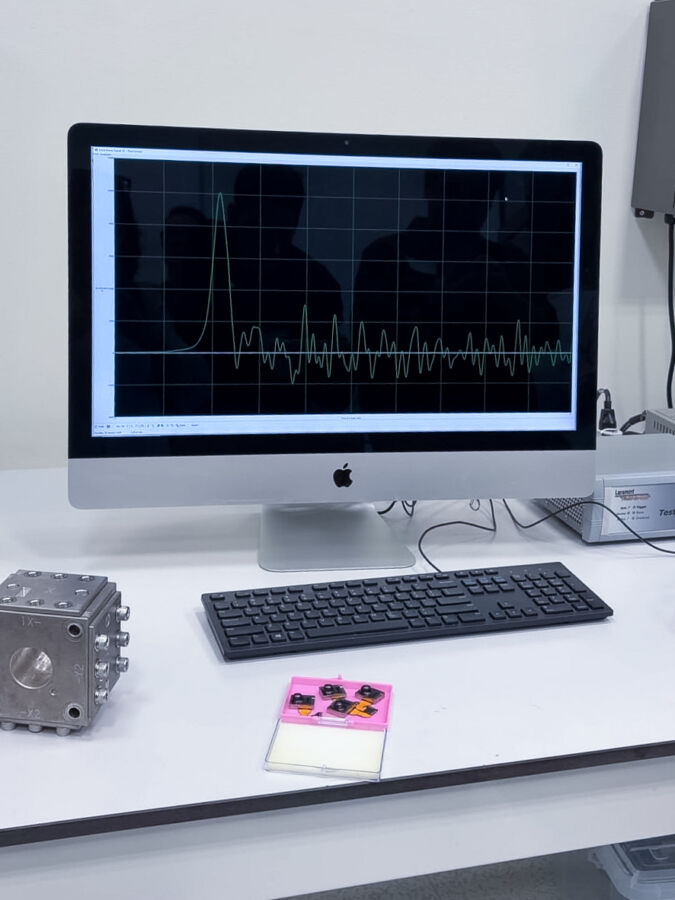

Mechanical Shock Testing simulates sudden, high-impact forces on the module that exceed those encountered in accidental drops of the phone. These tests are meant to identify structural vulnerabilities early in the design and assembly process and ensure camera components can withstand unexpected impacts.

This explains why the alignment of camera lenses is key to achieving crystal-clear focus in photos, and why the occasional drop has little to no impact on photo-taking quality. And this also explains why the testing environment for Shock Testing is notably intense, as multiple loud bursts of impact could be heard, and the area required hearing protection during observation.

To simulate long-term exposure to different environments, camera modules also undergo long heat-soak and Thermal Cycling Tests. This accelerates material expansion and contraction, helping engineers identify issues such as corrosion, warping, or fatigue in the materials and components that may develop over time.

Meanwhile, Liquid Thermal Shock Testing goes further by rapidly exposing camera modules to extreme hot and cold conditions, and these sudden temperature changes let Apple engineers check the material strength and the adhesive elements used to assemble components, much faster than with air-based tests. For those of you who love diving with your smartphone, or bring it along to take photos of the Northern Lights, this explains how your device can still hold up in harsh temperatures, even if your fingers cannot.

Lastly, Pressure Cooker Testing places camera modules simultaneously in an environment of elevated heat, humidity, and pressure. This accelerated stress is designed to reveal long-term reliability concerns, such as moisture ingress or material separation.

While we did not get to explore every part of the facility, focusing on camera durability gave us a clear view of Apple’s testing approach. Instead of just one test, camera modules face several overlapping stress scenarios that mirror and even exceed real-world use.

The main point is simple: Apple focuses on long-term reliability. Most people never see this part of development, but it’s what makes the iPhone feel dependable year after year. In addition to improving software, Apple uses device analytics (with user consent) to learn about both software and physical usage. This covers factors such as how devices are dropped, the angle at which they hit, and the amount of sunlight they receive, all of which, when compiled, help engineers design realistic lab stress tests and improve durability testing.