When it comes to e-commerce, speed is key. While it might be easy to keep an online inventory readily stocked, getting a product into a customer’s hands with haste is an endeavour Amazon has been relentlessly seeking to achieve.

Not satisfied with same-day deliveries, Amazon has evolved its delivery backend to offer sub same-day delivery for select products on their site for certain regions in the US. This means that from the moment of checkout, a customer could receive their order within five hours or less.

Having visited a facility in Bridgewater, Massachusetts, the combination of robots and an efficient workforce makes achieving such speeds possible. Unlike full-fledged fulfilment centres, a sub same-day facility does not carry a full range of items, but leans towards products that are high in demand and can be shipped out quickly, such as mobile phone chargers.

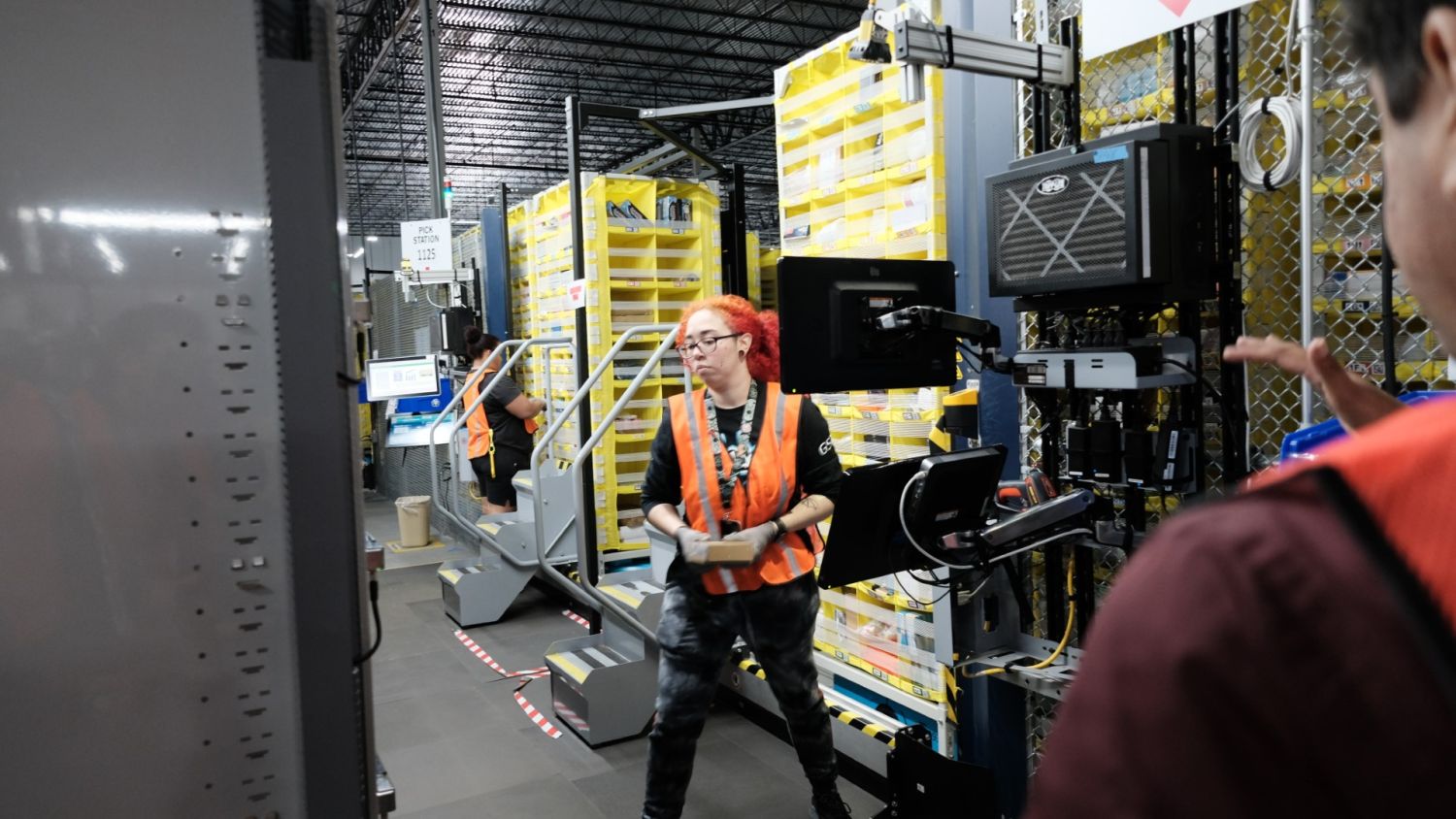

Organising the facility into specific areas where orders are sorted, picked, and packed, robots are key in helping Amazon achieve its delivery promise, and staff on the ground need not walk long distances to acquire items for shipment. Pretty much everything is handled within a small individual area, minimising wasteful motion.

Starting off with a sorting station, products are placed into cubby holes, each with labels to track individual items found within. The beauty here is that Amazon staff do not use a manual scanner to register each item as cameras are deployed to keep tabs on products being sorted away in a sub same-day facility. The system even illuminates cubby holes which are filled to capacity to encourage staff to file products away to a different section of the yellow rack.

Once filled, the entire yellow rack is moved around through the use of robots called drivers, which sit at the base of each stack. These drivers move autonomously and continually rotate racks with empty spaces to the sorting station.

These same drivers will also deliver products to another section of the Amazon sub same-day facility where products will be taken off the yellow racks and picked for packaging.

Once again, the area of operation is small and efficient. The staff has their hands freed up to handle only packages as a mounted scanner handles the rest.

Once picked, the products are packed and a shipping label is slapped on as an order makes its final journey out of the facility.

As the packages traverse the conveyor belt, there’s another sorting phase where each order is assigned to specific delivery routes to complete the journey in the Amazon sub same-day facility.

The 155,000-square-foot facility typically processes around 40,000 packages daily and is staffed by 85 individuals per shift. During peak periods like Black Friday, a network of sub-same day facilities can scale up to 1,000,000 packages daily to meet the demand of Amazon customers.

Globally, such facilities differ from market to market. However, it serves as a blueprint to give Amazon a good understanding and possibilities if such sub same-day speed is appreciated by the customer. In Singapore, Amazon Fresh offers a two-hour delivery window, which is critical when it comes to perishables, but we do have to consider how Singapore is geographically more compact compared to the US.

Regardless, with such speeds, we’re pretty certain that it’s this edge that will keep customers coming back for more.

Gerald currently straddles between his love of video games and board gaming. There’s nothing that interests him more than trying out the newest and fanciest gadget in town as well. He dreams of publishing a board game sometime in the future!